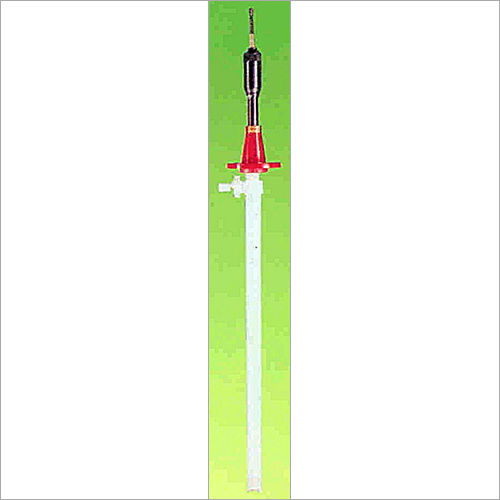

Barrel Pump Aluminium

Product Details:

- Color Sliver

- Product Type Barrel Pump

- Usage Industrial

- Material Aluminium

- Click to View more

X

Barrel Pump Aluminium Product Specifications

- Barrel Pump

- Sliver

- Aluminium

- Industrial

Product Description

Description :

- All wetted parts like pumping Chamber, Pump, Base, Discharge Tee, Nozzle, Wing Nut are made of SS-316 investment Casting.

- The outer & Inner Pipes are Seamless type Made of SS-316

- The Shaft is made of SS-316 Bright Bar

- The Guide Sleeve and Lip Seals are made of PTFE.

Salient Features :

- Seamless Design

- Self priming type

- Light weight & hence portable

- Modular design construction for easy maintenance

- All components are interchangeable

- Salves considerable time, labour & spillage

- High standard of quality & safety ensures reliable performance for handling Aggressive corrosive & Flammable Liquids

Technical Specification :

- 1150mm for Std 200 / 250 Ltrs Barrel

- Capacity 110 lpm at open discharge (Max)

- Head 21 Mtrs (Max.)

- Temperature - SS316 -upto 120oC

- Temperature - PP -upto 70oC

- Temperature - PTFE -upto 240oC

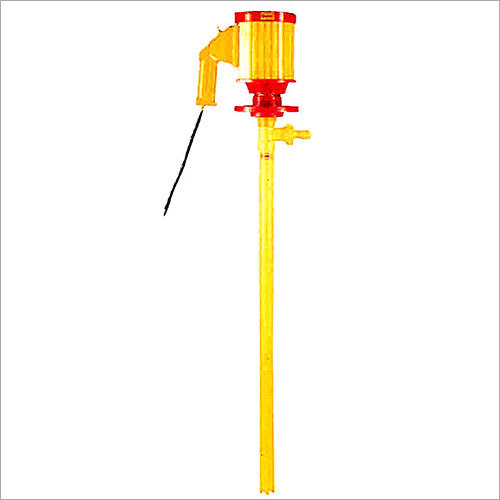

Drive Units available

- Flameproof Electric motor : TEFC, Single Phase, 220V, 50Hz, 0,7HP, 15000 rpm. AC/DC Electric Motor, Suitable for Gas Group I, II-1A & IIB

- Pneumatic Operated air Motor : Chicago Pneumatic make, In-built regulator type, 21,000 rpm, Working Pressure at 4 to 7 Bar Air Pressure & Consuming 25 cfm of air.

- Non-Flameproof electric motor : Single Phase, 220V, 50Hz, 0,7 HP, 15000 rpm, AC/DC type, Universal Electric Motor.

Application :

- SS Pump With FLP Motor : For almost all types of solvents, varnishes, Turpentine, Paints, Gasolene, HSD, Petroleum Products, Chloroform, Drugs & Pharmaceuticals, Decreasing Agents, Phenol, IPA, LDO, Water treatment Chemicals, Nitric Acid, Phosphoric Acid. Thermic Fluid etc.

- PP Pump With Hastalloy Shaft : For highly Corrosive Liquids like Conc. HCL, Dil. H2S04, HF, NA0H Formic Acid, Electroplating Solution, Photographic Developers, Salt Soln, Pesticides, Intermediates, Toxic Chemicals etc.

- PTFE BARREL PUMP : Suitable for all of the above.

Enter Buying Requirement Details

Other Products in 'Barrel Pumps' category

Mieco Pumps & Generators Pvt. Ltd.

GST : 29AABCM1475H1ZE

GST : 29AABCM1475H1ZE

162, Sadar Patrappa Road, Bengaluru - 560002, Karnataka, India

Phone :08045814693

|

MIECO PUMPS & GENERATORS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |